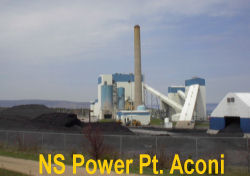

What is co-burning?  Both plants above use advanced FBC technology (Fluidized Bed Combustion)

Extracted from the Technology Factbook available at JAG's Website Hydrocarbon wastes from industrial sites are removed and used to supplement a hydrocarbon fuel, such as coal, to produce energy. Since both fuels are hydrocarbons, the blended fuel can be burned using technology similar to that used for the original fuel source. The exhaust material passes through filters and scrubbers for pollution control. Testing determines whether leftover ash requires further treatment before disposal.

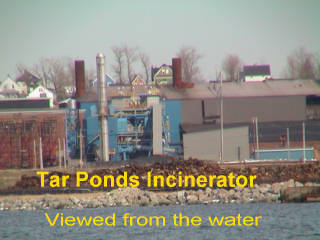

How does it work?There are three important components to co-burning - fuel blend preparation, fuel blend destruction in a furnace, and pollution control. Suitable contaminated material containing hydrocarbons is prepared by dewatering and screening to remove large material that would damage the furnace. The prepared waste is then blended with fuel either in batches or by slowly adding the contaminated material into the fuel feed line to the furnace. The operating conditions depend on the type of furnace. The furnace must be operated at a temperature sufficiently high to destroy the contaminants blended with the fuel, as well as any harmful materials in the fuel. The gases produced in the furnace pass through air pollution control equipment to remove most of the airborne metals, acids, and particles of ash. These wastes must be properly disposed of at an approved disposal site. The other cleaner combustion gases, such as steam and carbon dioxide, are released outside through a stack. The stack emissions are monitored on an ongoing basis to ensure emission targets have been met. The soil or ash remaining in the furnace after the burning may be treated and/or disposed of in a landfill or approved facility, depending on the quantity of contaminants remaining. The amount and concentration of organic contaminants remaining that require disposal is much less than the initial amount of waste that was burned. End of the excerpt from JAG's Technology Factbook Should we be concerned about Co-burning?No matter how you dress it up, co-burning is still incineration with all the dangers that go with it.Burning Tar Ponds Sludge at Point AconiPoints to be considered:

Dioxins and other deadly POPs (persistent organic pollutants) won't go away. They accumulate in your system where they remain over the years, and the body can't rid itself of these disease producing toxins. Scientists have found that dioxin and PCBs are found at extremely high levels in the breast milk of Inuit women of northern Quebec, hundreds of miles from the nearest known source! For more information on the dangers of incineration check out: |